About

Chrysler Building Spire Lighting Retrofit:

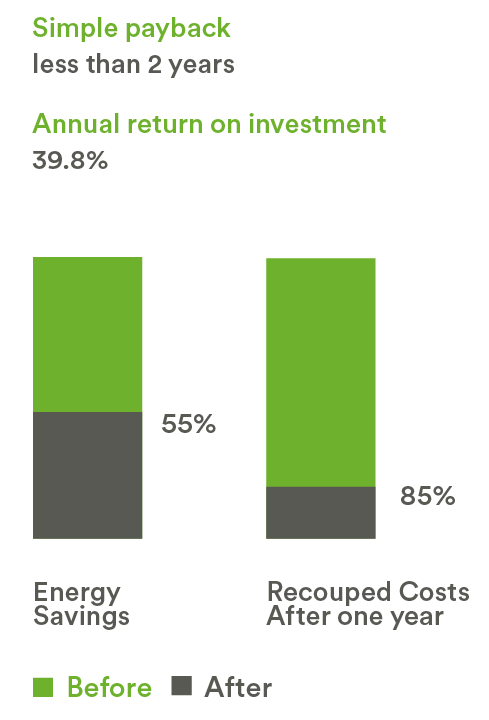

One of the highest profile lighting retrofits in the world, upgrading the lighting in the iconic chevrons of the Chrysler building spire, yielded 55% energy savings, greatly reduced maintenance, and will pay back in less than two years.

Process

The existing lighting of the 120 chevrons consisted of 30- and 32- watt T-8 fluorescent bulbs. Replacing each of these with 12- and 15-watt LEDs provided 55% energy savings and an estimated payback of less than six years. However, Tishman Speyer found the real savings in the massively reduced maintenance of the long-life LED lamps.

Design Conditions

In 2014, the team at Tishman Speyer knew there was a significant energy savings opportunity if the existing fluorescent chevron lighting could be swapped with LEDs, but there were concerns that a variation in color would change the character of this highly visible landmark. Sensitive to this, Tishman Speyer carefully researched the available colors of LED bulbs and selected one they felt was a perfect match for the warm, white light of the existing fixtures. This being New York City, interested parties weren’t necessarily ready to take their word for it; so a pilot retrofit was conceived. They swapped out the lights in just one of the chevrons with the new LEDs and asked anyone interested if they could tell which it was. After a few weeks, and many friendly challenges to try and pick out the LEDs, no one was able to distinguish the rogue chevron, and Tishman Speyer moved forward with the retrofit.

Project Team

Project Owner

Tishman Speyer

Performance

The existing lighting of the 120 chevrons consisted of 30- and 32- watt T-8 fluorescent bulbs. Replacing each of these with 12- and 15-watt LEDs provided 55% energy savings and an estimated payback of less than six years. However, Tishman Speyer found the real savings in the massively reduced maintenance of the long-life LED lamps.With 3-5 fixtures for each chevron, and with seven levels of chevrons laid out over a spire that is 150 feet in height, bulb replacement was a more complicated, labor intensive project than many might assume. A significant portion of the fluorescent bulbs required replacement every two years, with some ballast replacements needed every four. With LED fixtures, the items most likely to need replacement are the drivers, which have 5-year warranties. Typically, LED bulbs last for longer. The labor saved with the introduction of long-life LEDs meant the project recouped 85% of its capital costs in the first year, with total payback in less than two years. With such a short payback, and a limited capital cost outlay, the project did not pursue electricity savings incentives from the local utility.

Benefits

Between energy savings and reductions in maintenance, Tishman Speyer will achieve total payback in less than two years, while obtaining 55% energy savings.

Conclusion

The Chrysler spire lighting retrofit is a classic example of a simple LED retrofit with an incredibly quick payback. To ensure that one’s time and energy are well spent, we recommend that anyone pursuing a similar retrofit perform adequate due diligence, as Tishman Speyer did. In addition to addressing potential aesthetic issues, careful attention should be paid to the warranty of each element of the system under consideration (look for 5-, 7-, or 10-years), fixture efficiency near 100 lumen/watt, an LED Color Rendering Index (CRI) greater than 80, and whether selected technologies meet any threshold requirements needed to access financial incentives (such as DLC or Energy Star certification.) When the right steps are followed, significant savings are within easy reach for most buildings.