envelope

The building envelope affects occupant comfort and energy costs more than any other building system.

Efforts to optimize energy performance in buildings often focus on improving individual components, like selecting high efficiency mechanical equipment. A more holistic approach includes a focus on driving down the basic demand for energy and understanding how all systems interact with one another. High performance building envelopes are key to this more holistic approach as they can significantly improve the overall comfort and energy performance across the lifespan of the building.

key benefits

- mitigates drafts and uneven temperatures

- improves indoor air quality

- lowers heating and cooling bills

- reduces noise, odors, and pests

- improves building durability and longevity

benefits of building high performance

Airtightness, high performance glazing, continuous insulation, and thermal bridge mitigation work synergistically to create high performance building envelopes that deliver practicality, longevity, quality, ease of maintenance, and superior comfort.

- airtightness improves indoor acoustics and controls odors

- the regulation of temperature and elimination of hot and cold spots dramatically improves thermal comfort

- daylight and access to views helps increase occupant wellbeing and productivity

- when paired with ventilation, a high performance building envelope controls airflow and delivers fresh, filtered air into interior spaces, improving occupant health

- high performance building envelopes reduce condensation and protect against mold and moisture damage

- quality construction prevents pests from entering the building

- investing in a high performance building envelope reduces recurring maintenance and replacement costs related to mechanical equipment

- rising demand for healthy, comfortable, and sustainable buildings increases value of high performance building envelopes

- incentives and investment programs lower first cost

- good craftsmanship and investment in quality materials lowers maintenance and replacement costs

A high performance envelope can be made using nearly any type of construction, whether it is mostly opaque walls with a series of windows or curtain walls of mostly glass, so long as the following strategies are achieved:

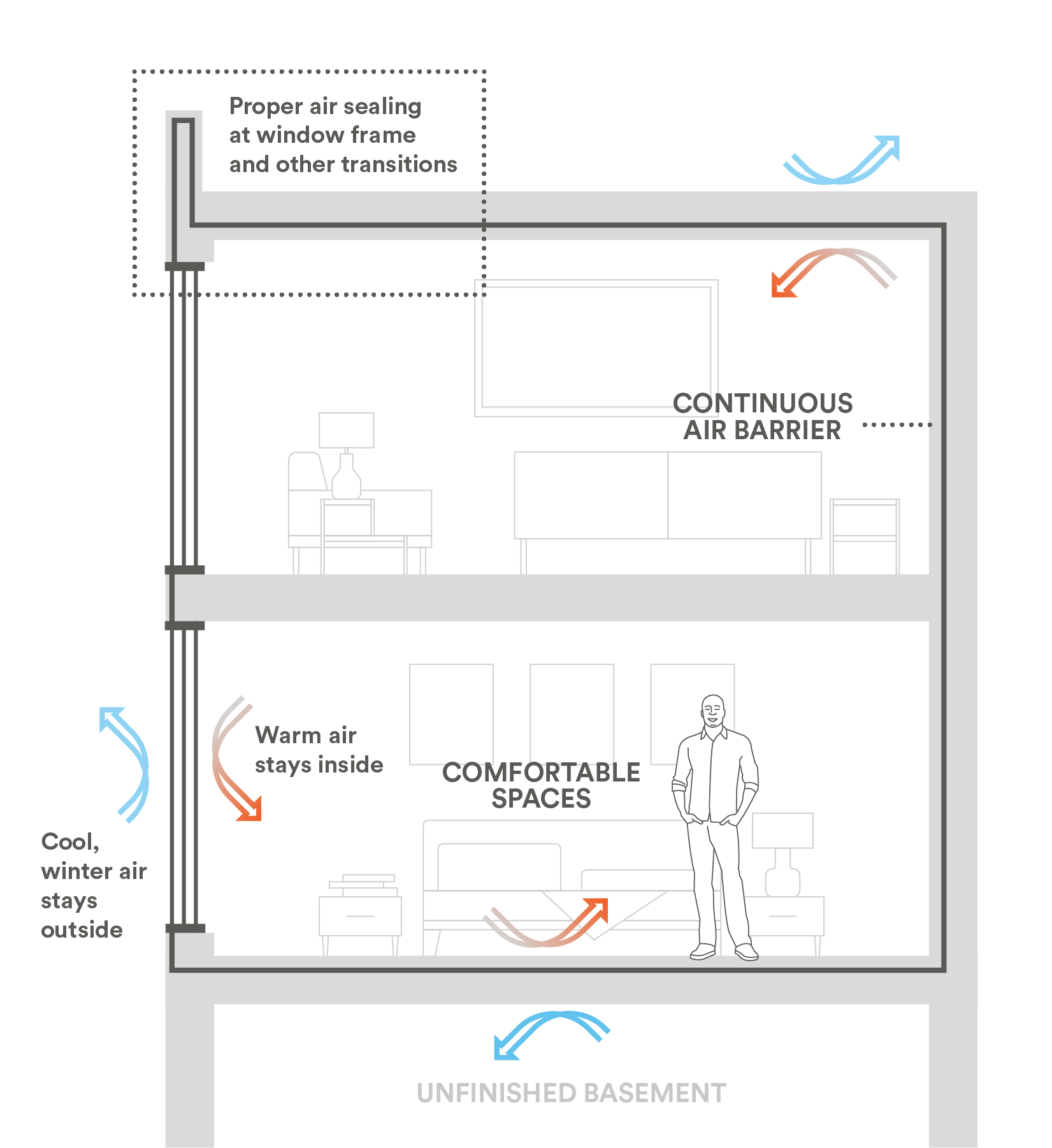

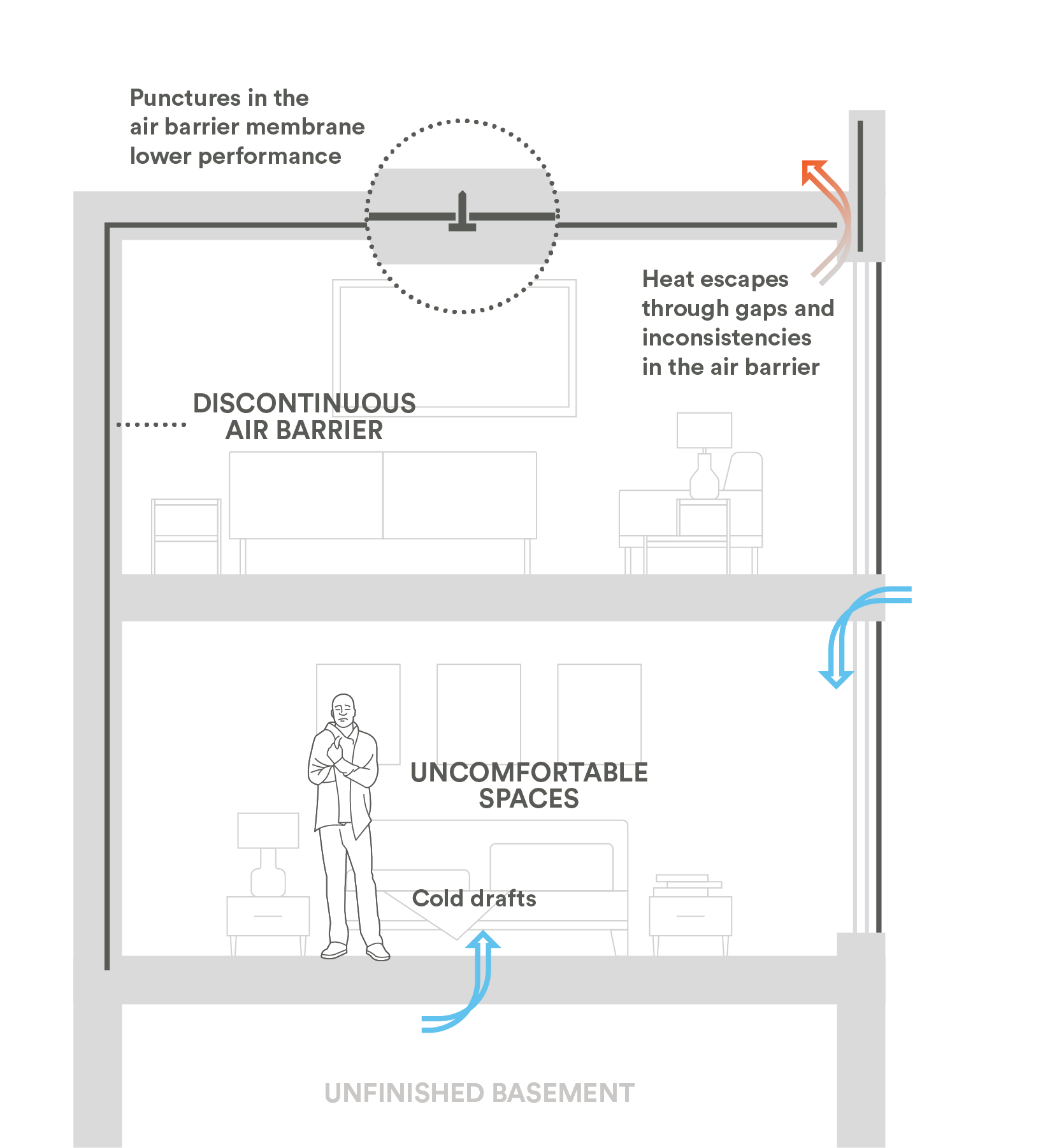

An airtight building is critical to efficiency and comfort. Airtightness is achieved by wrapping an air barrier around the entire building and ensuring that transitions between windows, doors, glazing units, air vents, and other envelope openings are well-sealed. An airtight building helps keep out noise, odors, and pests, and improves energy performance by reducing air leakage and drafts.

airtightness

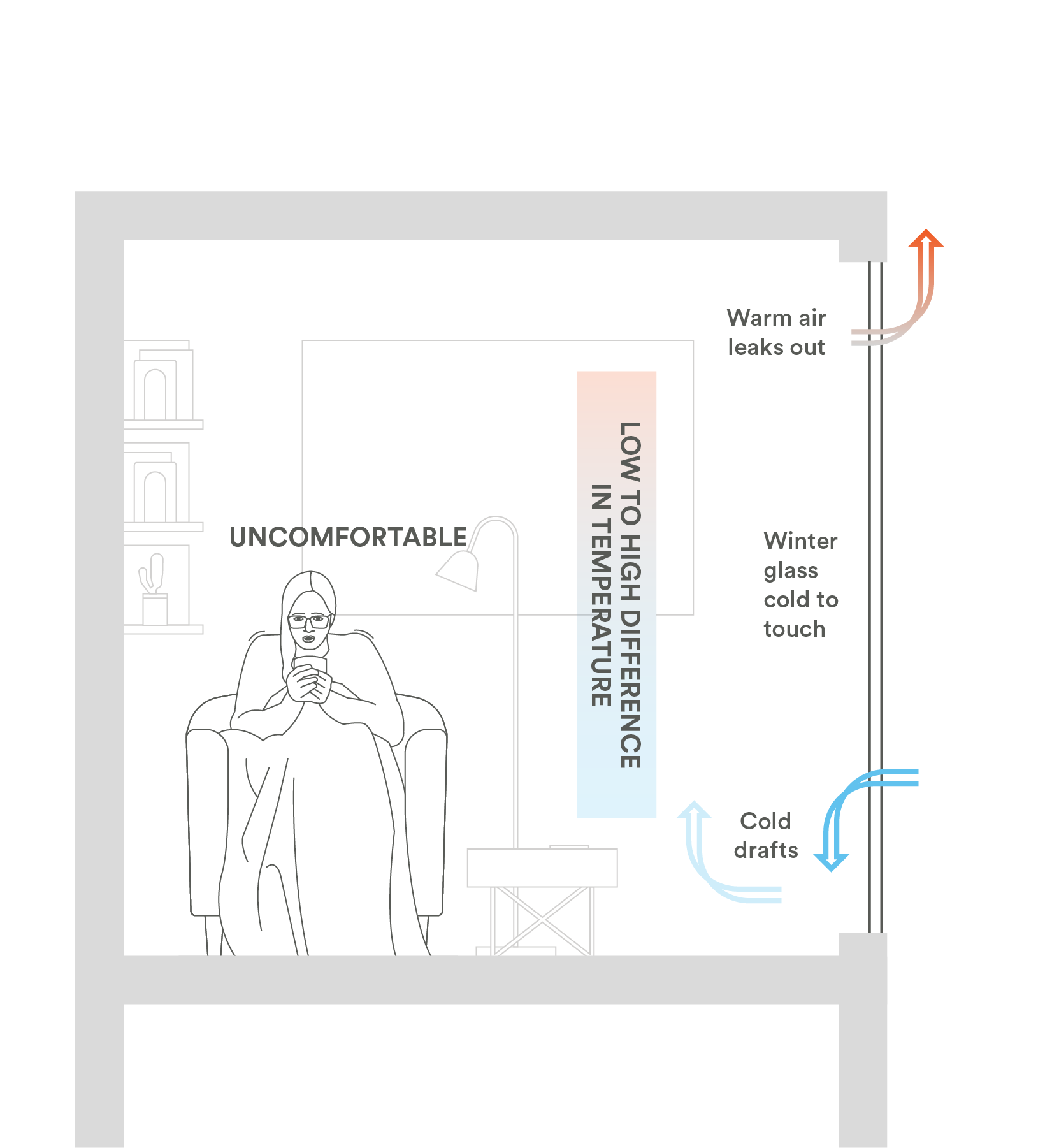

Without an airtight, continuous air barrier, warm air seeps out during the winter and in during the summer, resulting in uncomfortable occupant spaces, issues with moisture and condensation, and unnecessarily high heating and cooling bills.

key benefits

- mitigates condensation, mold growth, and deterioration

- when paired with ventilation, creates healthier indoor spaces by improving indoor air quality

- lowers demand on heating and cooling

- eliminates drafts

- improves acoustics and privacy

process

Airtightness requires attention to detail, where each and every transition needs to be successfully sealed. Building plans should incorporate air barrier materials at every point along the envelope assembly and specify how these materials will be joined up to create an unbroken, airtight layer.

Airtightness and proper ventilation are closely connected. Neither is effective without the other, and if either is suboptimal it is virtually impossible to provide a quality interior environment or to use energy efficiently. In airtight buildings with proper ventilation, filtered fresh air enters the building and stale air is exhausted at specific, controlled points, such as vents and operable windows.

Components

A building’s airtight layer is made up of a series of materials that fall into the following three categories:

- an airtight membrane that makes up the bulk of the air barrier surface

- pre-manufactured elements like windows and doors

- air barrier accessories, such as tape, caulk, flexible boots, and other sealants that seal transitions between the airtight membrane and premanufactured elements or building penetrations.

tips

- assign an Air Barrier Superintendent who coordinates tradespersons and ensures punctures or installation errors are corrected

- conduct blower door tests to assess the airtightness of the building, locate air leakages, and assess energy losses resulting from those air leakages

sick building syndrome

Many people mistakenly identify airtight buildings withsick building syndrome (SBS), in which mold and other pollutants are allowed to infest a building. While buildings with SBS typically have no operable windows, they are not actually airtight—in fact, their leaky envelopes are often the point of entry for moisture, mold, and other pollutants. SBS also often results from mechanical systems that lack fresh air supply or proper filtration and were poorly installed and/or maintained. High performance envelopes are the cure for sick building syndrome, not the cause.

on-site coordination

Constructing a high performance building envelope can require more precaution, closer attention to detail, and additional training for contractors and sub-contractors.

- ensure the airtight layer is continuous by taping all seams in the air barrier material, all transitions from windows to walls, and all vent, pipe, and other openings

- take a vigilant attitude about the air barrier by immediately reporting and repairing and punctures or tears in the air barrier if accidentally damaged on site

- ensure no nails, screws, or other fasteners are installed through the air barrier

- conduct building envelope testing, such as blower door tests to ensure airtightness and waterproofing

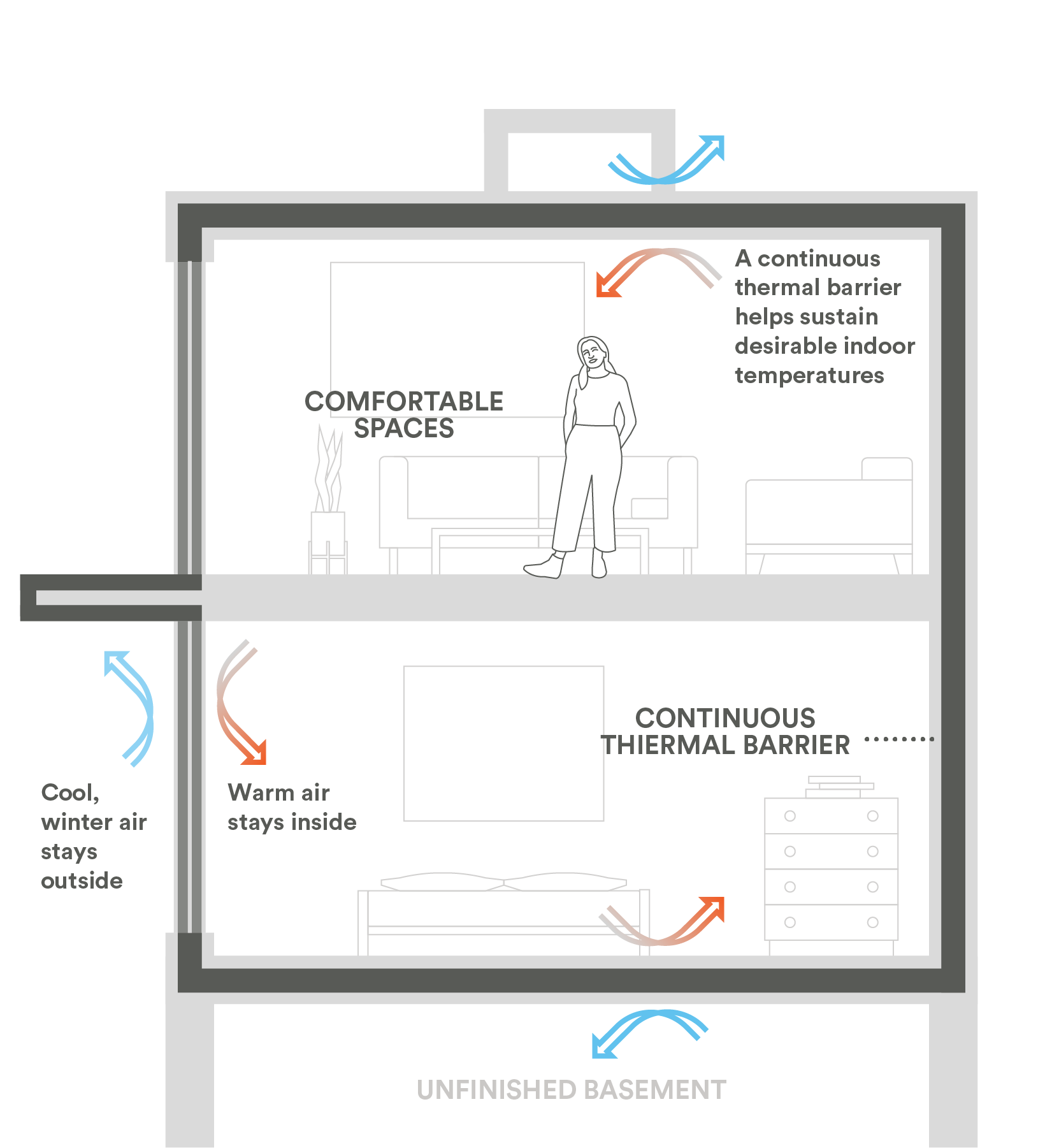

Continuous, uninterrupted insulation that wraps the entire building and is coordinated with thermal breaks in windows, doors, and cladding systems, will effectively reduce pathways for heat to travel in and out of the building, thus minimizing the need for heating and cooling.

continuous insulation

Continuous insulation works to maintain consistent indoor temperatures by eliminating pathways for heat to travel in and out of the building. Optimizing the type, amount, and location of insulation can greatly improve comfort and lower energy consumption.

benefits

- minimizes undesired heat loss and gain, lowering demand on the building’s heating and cooling system

- reduces condensation and protects against moisture damage

- regulates temperature, increasing thermal comfort

process

Insulation effectiveness is measured in terms of its thermal resistance or R-value, with higher values representing greater effectiveness. A material’s R-value depends on its thickness, density, and, in some instances, its age and moisture accumulation.

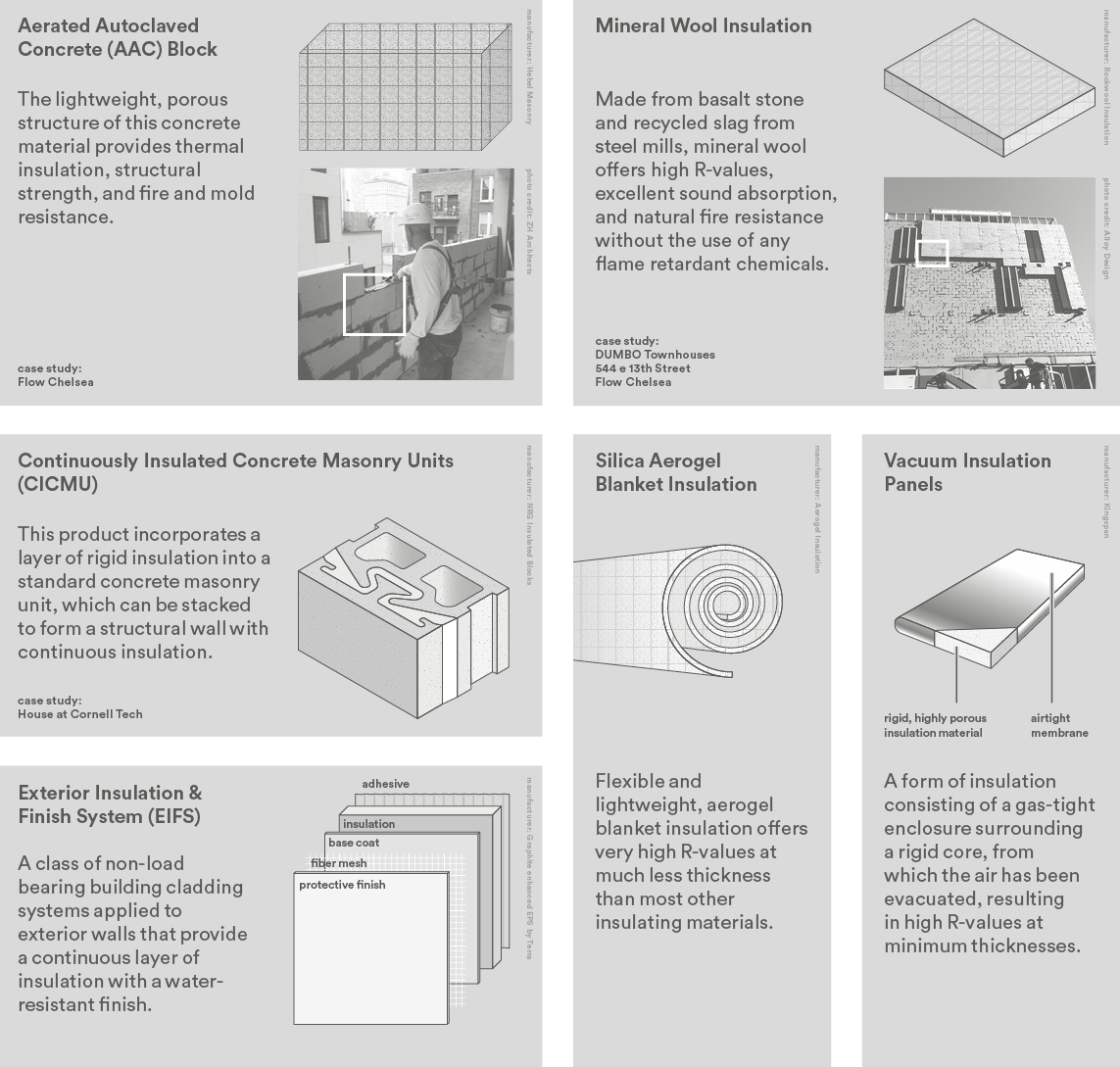

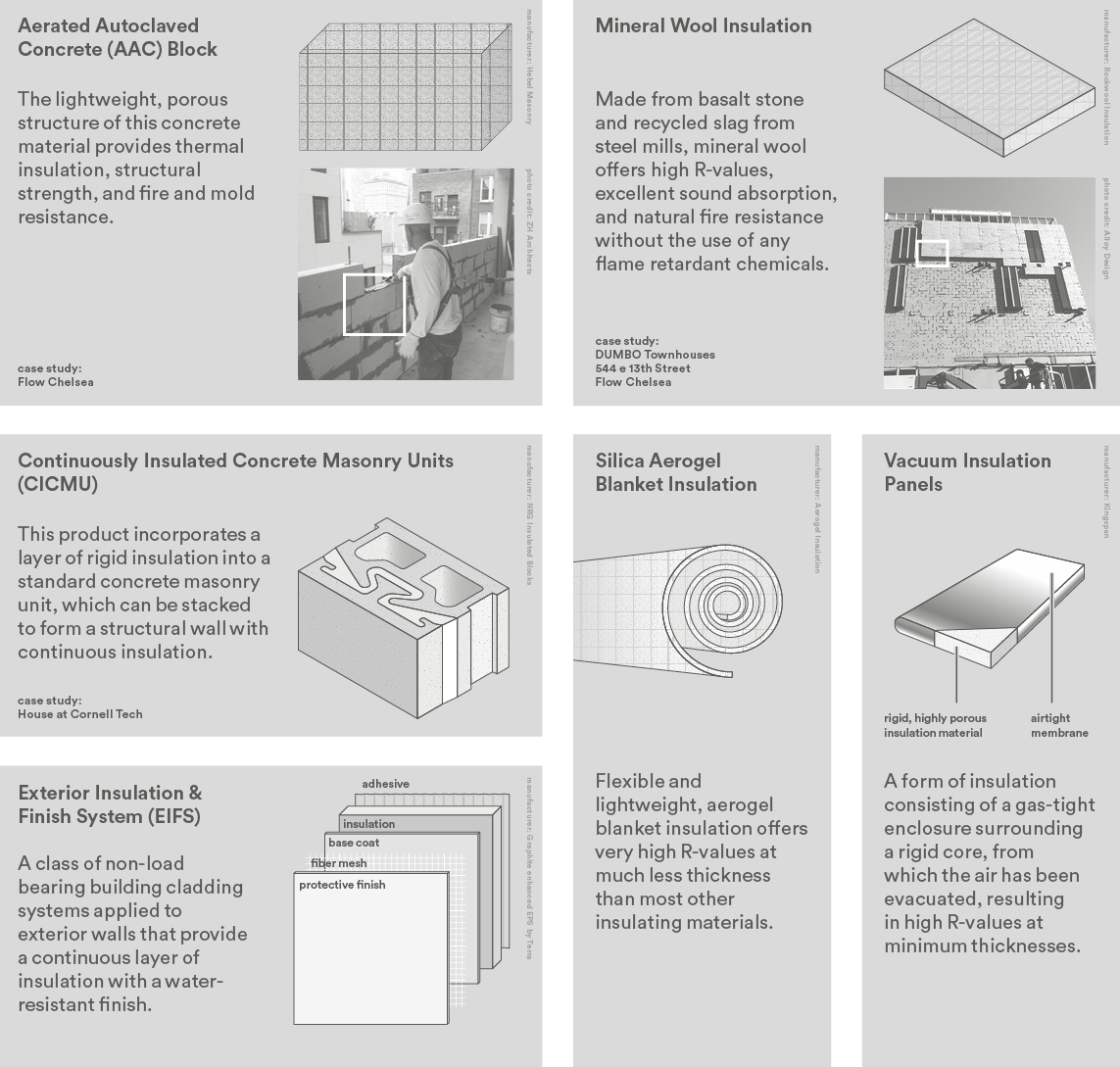

When upgrading existing buildings, it is best to apply insulation from the exterior in the form of a rainscreen or External Insulation and Finish System (EIFS). However, due to costs, lot line restrictions, historic preservation restrictions, and other limitations, building renovations often require applying insulation from the interior, leading to scenarios where it is more difficult to effectively insulate the whole building. Nevertheless, even imperfect interior insulation upgrades can vastly improve building performance.

Components

Different types of insulation materials such as rigid board, batts and rolls, loose fill, and spray foam, are each suited for specific interior or exterior applications. For building retrofits or challenging architectural conditions, innovations in insulation technology have resulted in high preforming products that provide high R-values relative to weight and bulk, or additional insulating capacity to standard materials, potentially improving their utility in problematic scenarios.

tips

- utilize energy modeling software to analyze the movement of heat and moisture through the building envelope and help determine how much insulation is needed in specific areas of the building

- always design insulation in tandem with thermal bridge mitigation to maintain the integrity and performance of the thermal barrier

passive design

Many high performance building strategies are passive, using little to no technology, and remain effective throughout the life of the building. Examples of passive design strategies include consideration for a building’s orientation, form, location, and window-to-wall ratio.

Incorporating passive design strategies early in the design process diminishes reliance on add-on technologies and mechanical systems that increase life-cycle costs of the building.

- in a temperate climate such as that of NYC, building envelope design must balance minimizing heat gain in the warmer months and minimizing heat loss in the cooler months

- install a green roof to increase insulation and reduce local heat island effects

- if the building lot allows, orient the building to receive maximum energy from the sun

- use vegetation and other landscape design strategies to help control heat gain and protect against wind and noise

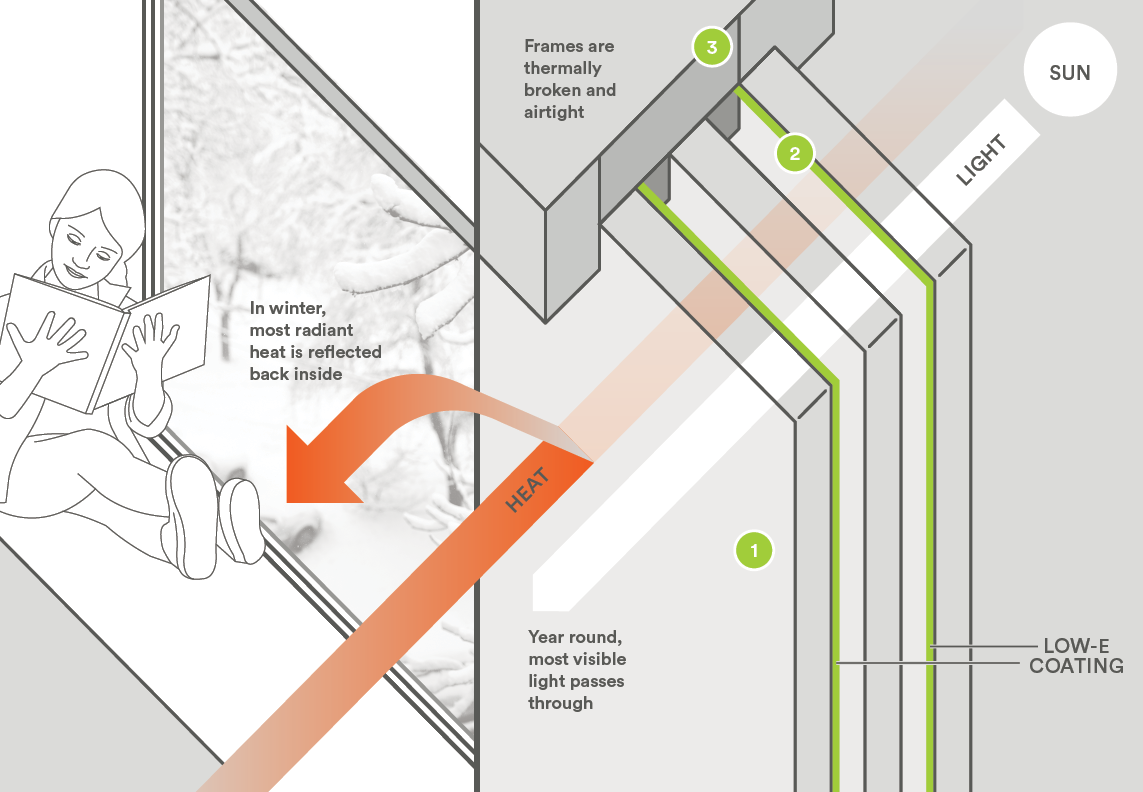

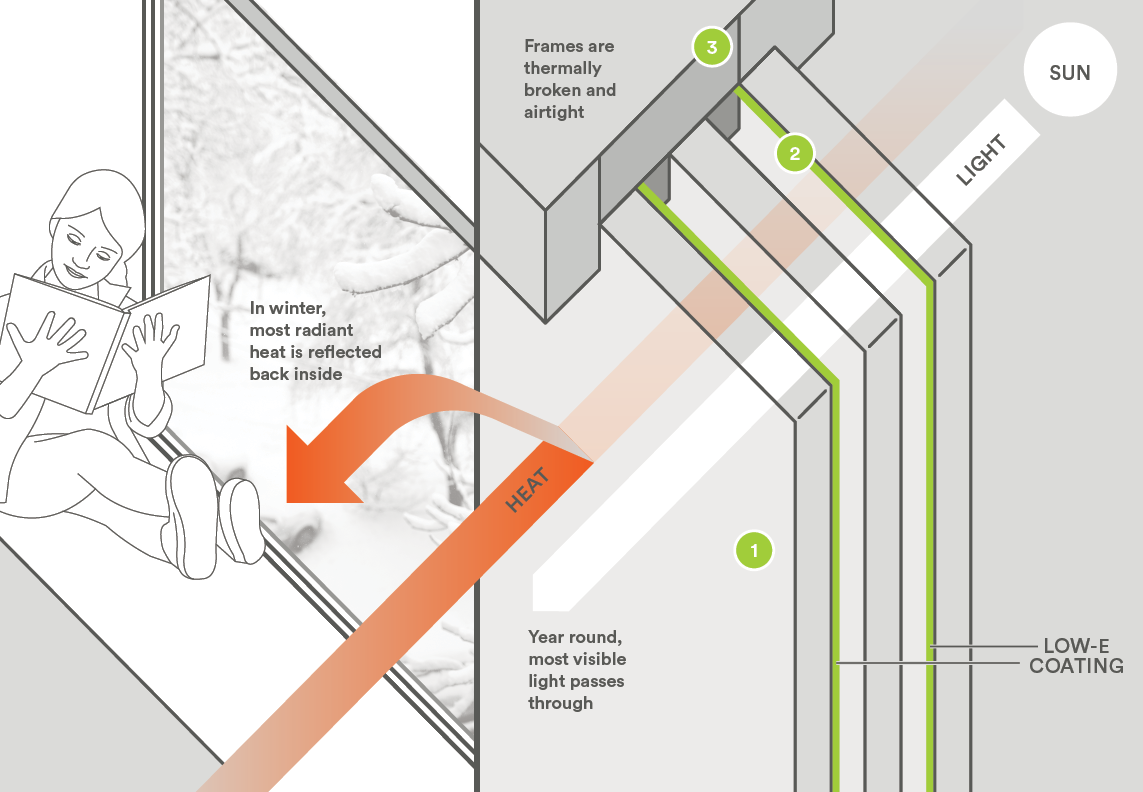

Most glass buildings of the past are highly inefficient, but new, sophisticated glazing technology can far outperform them. Combined with automated shading systems and thermally broken, airtight frames, high performance glazing reduces heat gain and minimizes glare while providing building occupants with attractive views and ample daylight.

high performance glazing

High performance glazing allows daylight into interior spaces and controls heat gain, saving energy while creating a dynamic environment that improves occupant productivity and wellbeing.

benefits

- lowers demand on heating and cooling by controlling heat gain

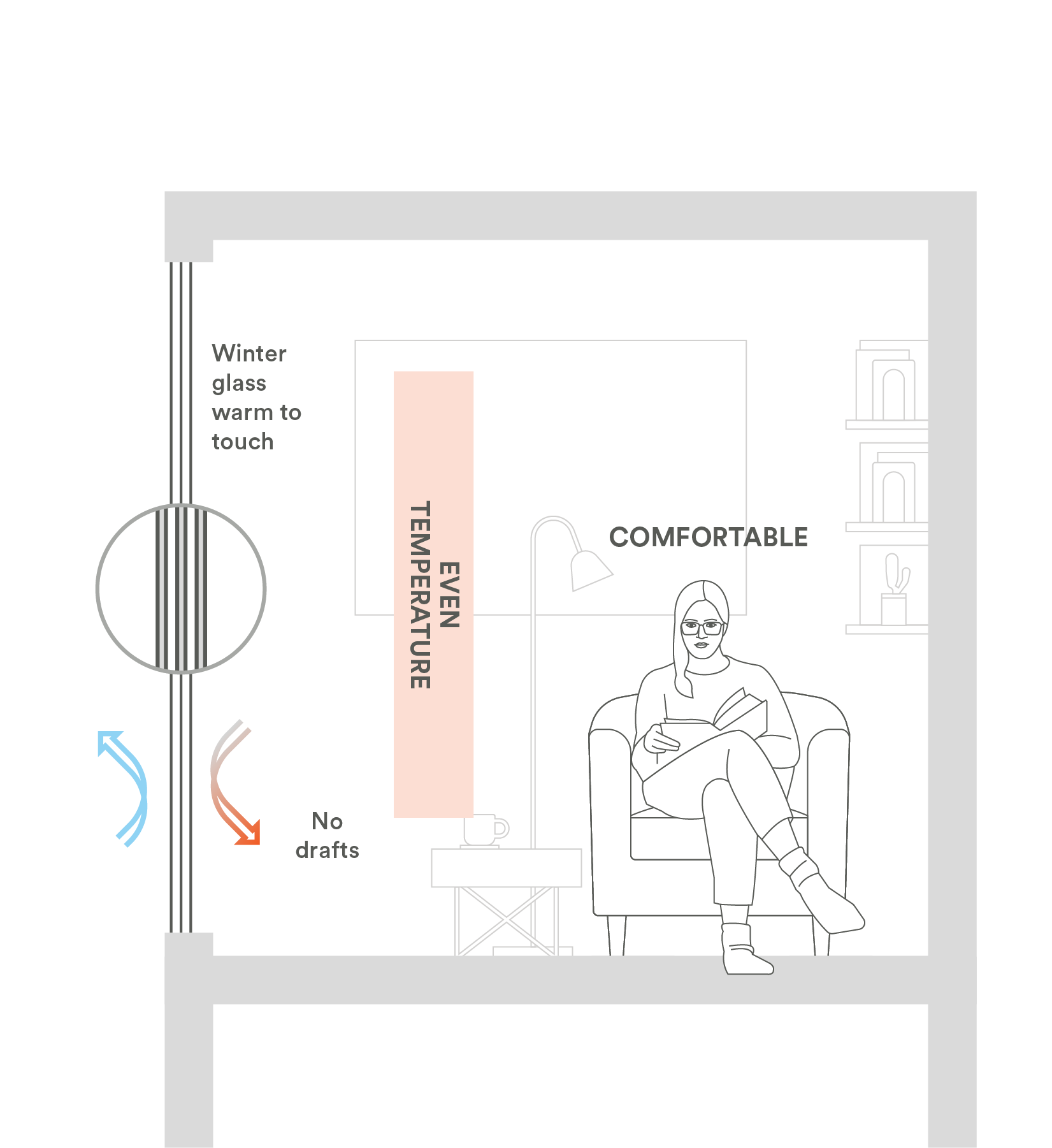

- increases indoor comfort in areas directly beside glazing that would otherwise be too hot or too cold

- increases occupant productivity and wellbeing by allowing access to views and natural light

- reduces demand for electric lighting

process

The amount of glazing used on the building, known as window-to-wall ratio, the orientation of the glazing, and the type of glass, are all important variables affecting indoor comfort and energy performance. These variables will impact a building’s heating, cooling, and lighting loads, and define access to daylight, natural ventilation, and views.

New innovations in glazing manufacturing have improved the insulation quality of glass. Combined with indoor and outdoor shading strategies, high performance glazing can reduce unwanted solar heat gain while allowing daylight to enter spaces. One of the most notable benefits of high performance glazing is that indoor spaces directly adjacent to the glass are much more comfortable and therefore better utilized.

components

When specifying glass, consider properties such as U-factor, Solar Heat Gain Coefficient, visual transmittance, and airtightness. To control heat gain and reduce glare, use applications such as fritting or laminated coatings to provide shading, as well as elements like louvers, overhangs, and automated interior shades.

- Insulated Glazing Units (IGUs) can be made with two or three layers of glass and are filled with inert gas that provides insulation. Triple glazing performs particularly well in increasing indoor comfort in spaces used for sedentary activities.

- Low-e coatings prevent heat from entering the interior space during the summer and escaping to the exterior during the winter.

- High performance glazing is not complete without thermally broken frames with robust gasketing and warm-edge spacers that reduce unwanted heat transfer.

tips

- within the wall assembly, place glazing units in line with the plane of primary insulation to ensure continuity of the thermal barrier

- properly air seal glazing units to reduce heat transfer due to air leaking through gaps around the window frame

daylighting design

Daylighting is the controlled admission of natural light into a building to reduce electric lighting, save energy, and create stimulating and productive indoor spaces.

Daylighting systems pair fenestration with interior or exterior shading devices and a responsive lighting control system to minimize glare, balance heat gain and loss, and respond to sunlight’s natural variations.

- design window size and spacing to optimize daylight and specify high performance glazing to control heat gain

- incorporate light shelves and solar shading devices, such as louvers or overhangs, to control how and when daylight enters interior space

- pair mechanical shades with daylight sensors that automatically lower or raise shades based on natural light levels

- incorporate daylight-optimized interior design, which includes space planning, furniture design, and interior finishes

- use an integrated design approach that addresses building form, siting, and climate, all of which influence the performance of the daylighting system

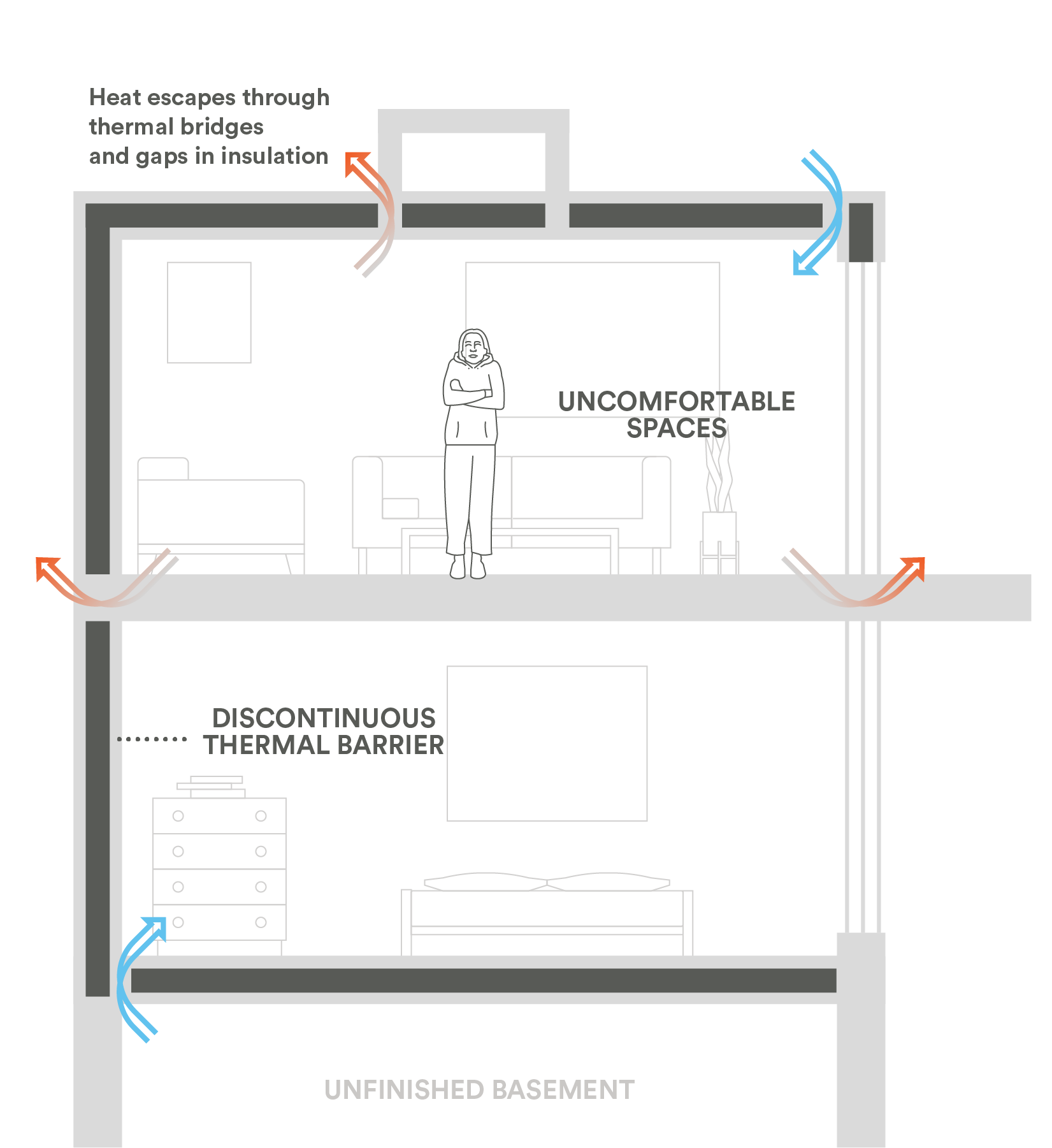

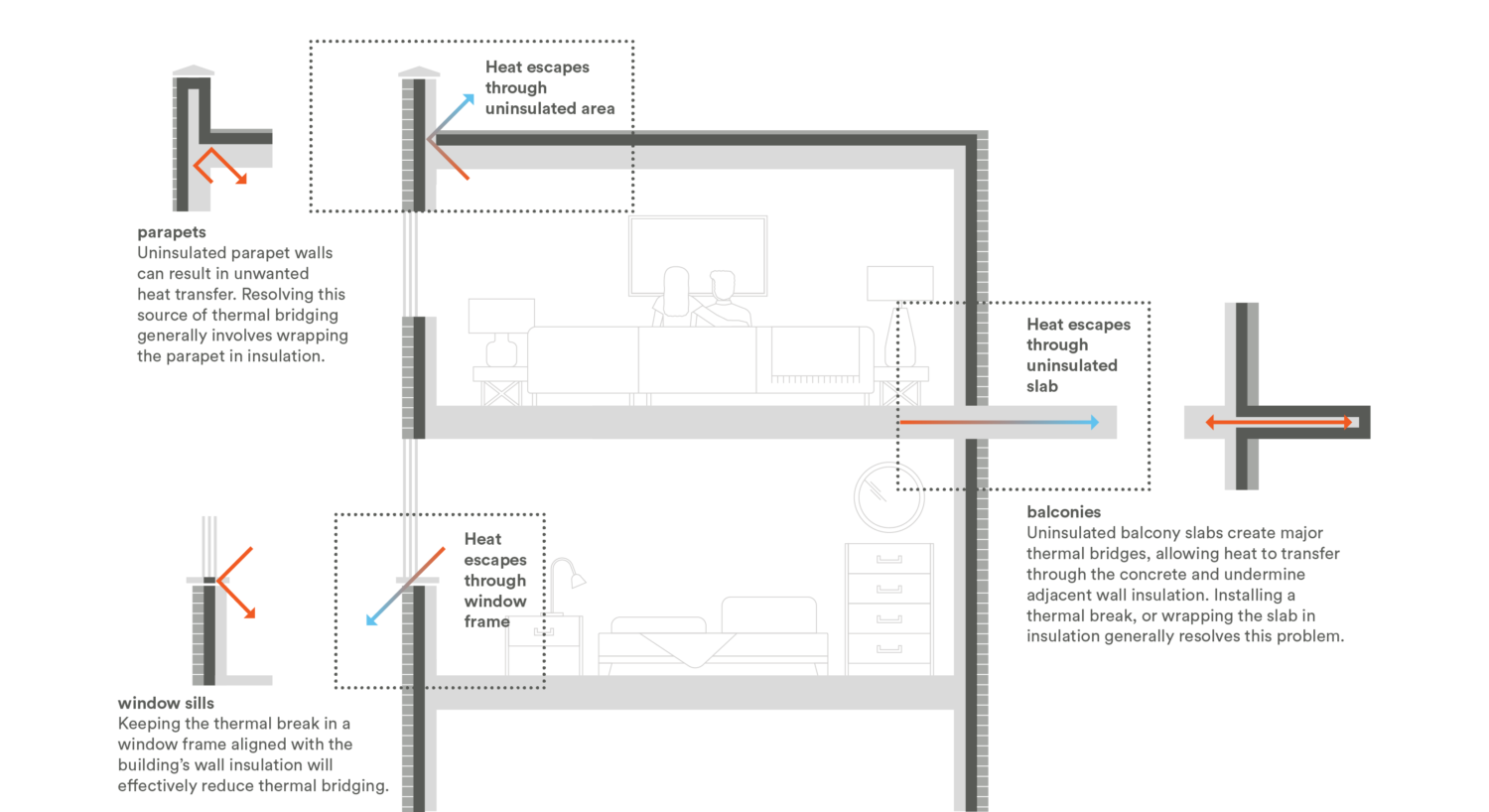

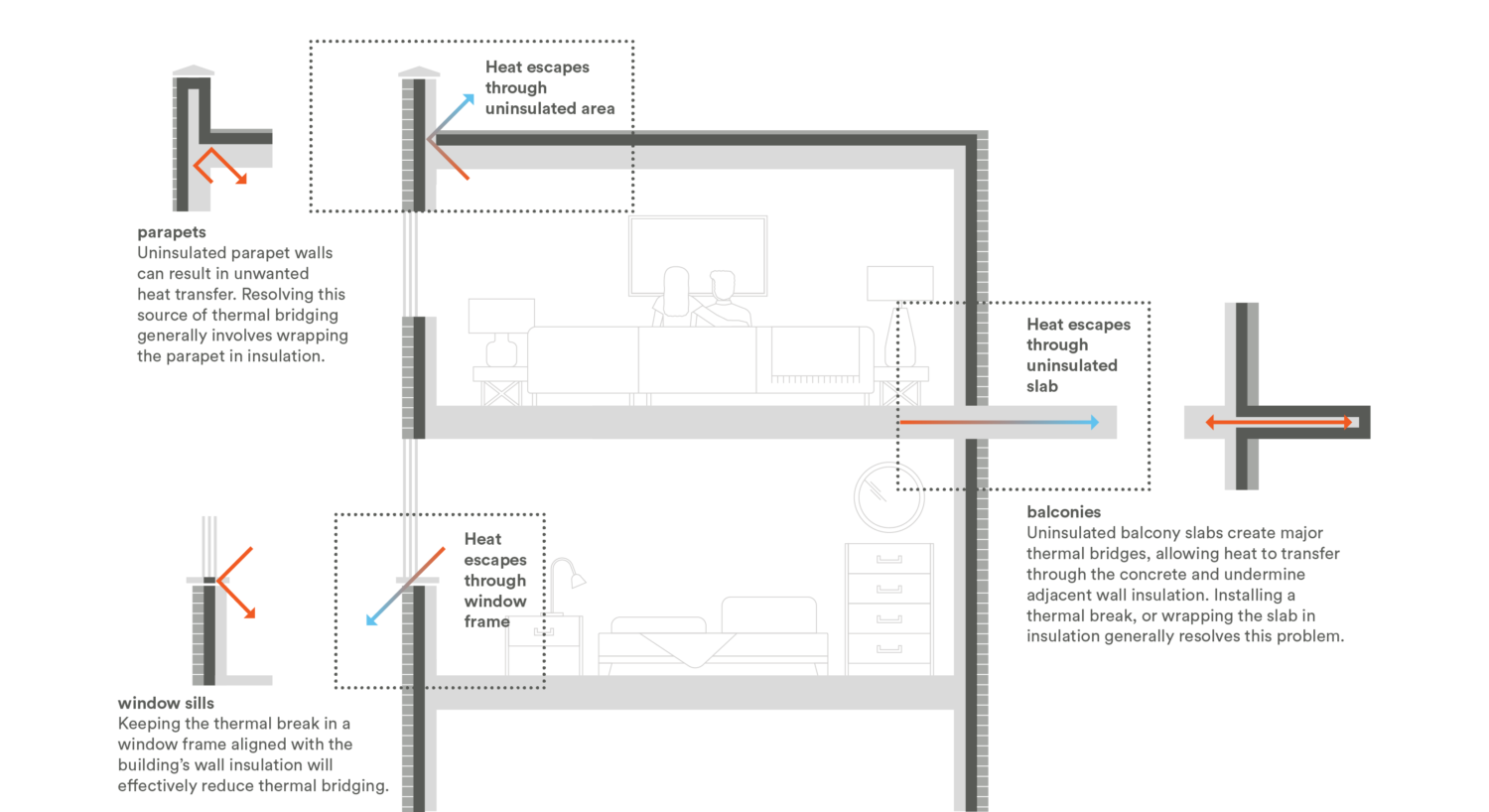

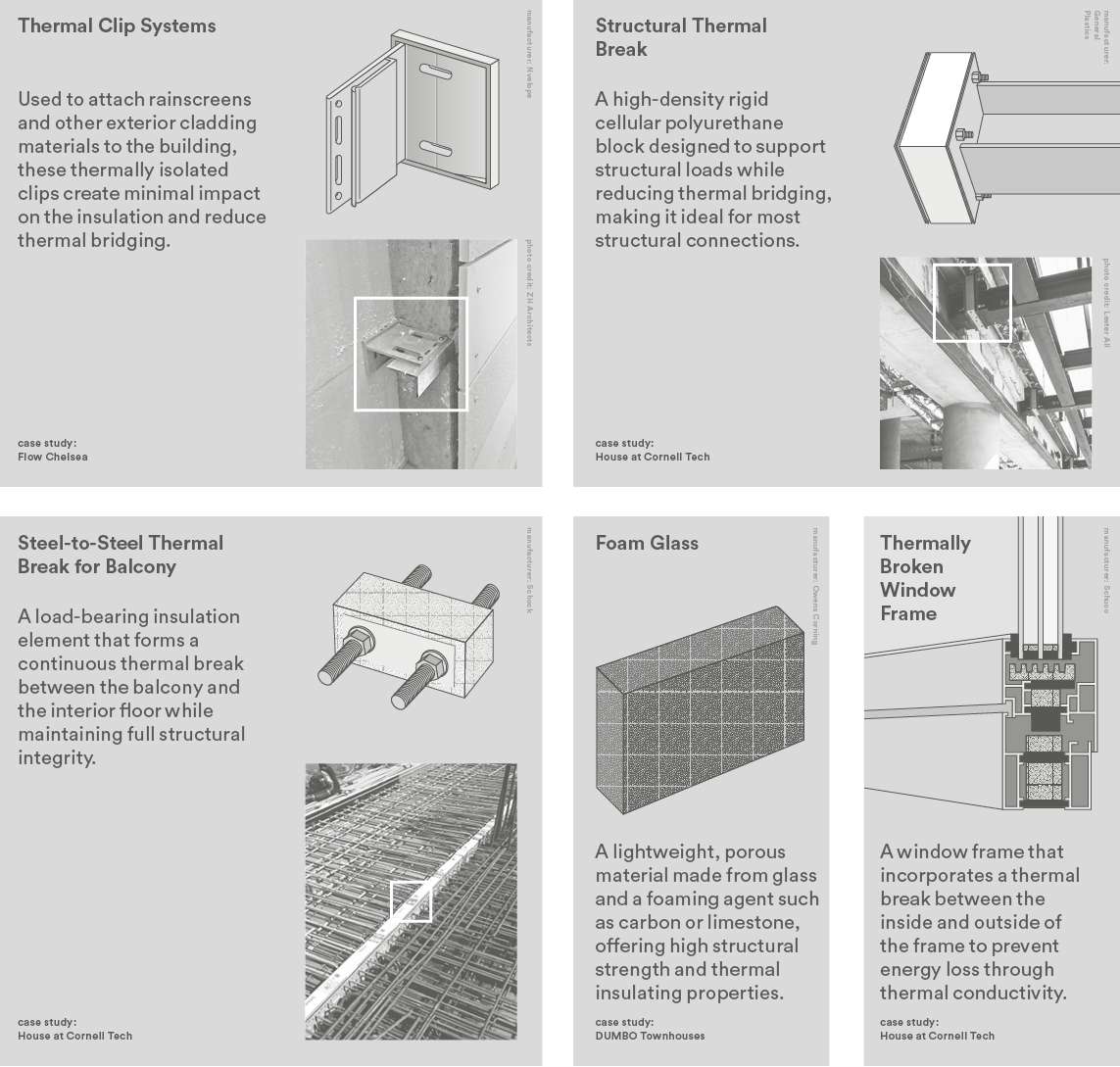

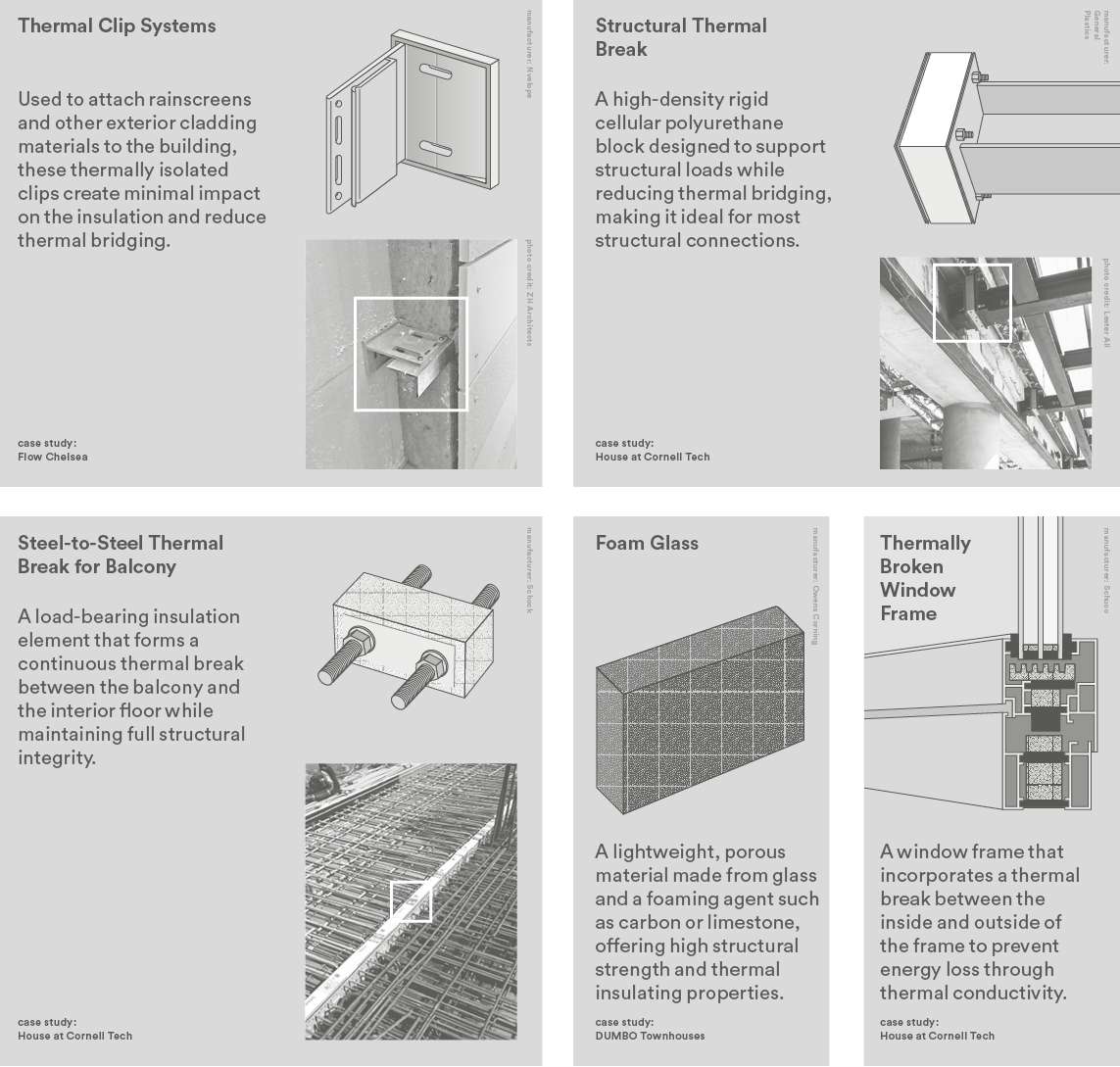

Mitigating thermal bridges is key to supporting the effectiveness of insulation and maintaining energy performance. Thermal bridge mitigation strategies include careful architectural detailing and coordination of building components, as well as specifying thermal breaks where needed.

thermal bridge mitigation

Identifying thermal bridges and designing solutions to eliminate or remediate them helps maintain a continuous thermal barrier across the building envelope, which is fundamental to energy performance.

key benefits

- lowers energy consumption by reducing heat transfer across the building envelope

- increases indoor comfort by eliminating hot and cold spots

- mitigates condensation and protects against mold and moisture damage

process

The most common type of thermal bridge is caused by structural elements used to connect the building envelope back to the building’s structural frame, such as metal anchors and ties. Other common thermal bridges occur at junctions between two or more building components, such as window- and door- to-wall junctions, as well as balcony-to- wall and parapet-to-roof junctions.

Identifying and mitigating all thermal bridges in a building can be a tedious but critical task, as even small thermal bridges, such as masonry ties, can add up to significant energy loss.

The objective of most thermal bridge mitigation strategies is to reduce

the number of building components spanning from exterior to interior and ensuring that each include a thermal break material that reduces heat flow through the component.

components

A vast number of thermal break materials and products are available on the market. Typically composed of fire- resistant fiberglass or resin composites, these materials are low conductivity and often have a high compressive strength for use as structural thermal breaks.

On the occasion when a thermal bridge is necessary, specifying materials with the lowest possible thermal conductivity can help reduce its impact.

Tips

- thermal bridge modeling tools can assist design teams in the evaluation of thermal bridges at complex or unique conditions

- finding thermal bridge locations in existing buildings can be done through visual inspection and thermal imaging cameras

pre-construction coordination

The architect plays a key role in the successful design and construction of a high performance building envelope. Architects must detail each building condition to ensure that all envelope components are correctly coordinated.

- ensure continuity of thermal, air, and vapor barrier through careful detailing and collaboration with consultant or contractor

- design construction details for proper sequencing and ease of assembly

- specify compatible products and ensure contractors are familiar with installation

- use energy modeling software to evaluate energy performance early and often, as making decisions too late in the process will be both costly and ineffective

- integrate the building envelope with other building systems such as lighting, shading elements, HVAC systems, and building controls to increase energy performance and savings