About

The City of New York is leading the way to reduce energy use, carbon emissions, and utility costs by implementing innovative steam system technologies in City-owned buildings.

Most NYC buildings rely on steam heating systems that often perform poorly, making occupants uncomfortable, wasting energy, and driving up costs. While many steam problems can be resolved using well-proven measures (see our Better Steam Heat guide to learn more), others remain more challenging. Fortunately, innovative technologies have emerged to help tackle some of these more complex steam issues. The City is testing a number of these in municipal buildings, helping other building owners to evaluate and navigate technology options that might be right for them.

Process

NYC DCAS Energy Management is leading NYC’s efforts to reduce carbon emissions 80% by 2050. Through their IDEA program, DCAS is helping to verify the performance of innovative, energy efficiency solutions and accelerate their adoption across NYC buildings of diverse types and uses.

To test the viability of steam solutions emerging in the NYC market, the NYC Department of Citywide Administrative Services, Division of Energy Management (DCAS DEM) conducted demonstrations of three technologies. Funded by DCAS DEM’s Innovative Demonstrations for Energy Adaptability (IDEA) Program, the demonstration projects were carried out in municipal buildings of diverse types and uses.

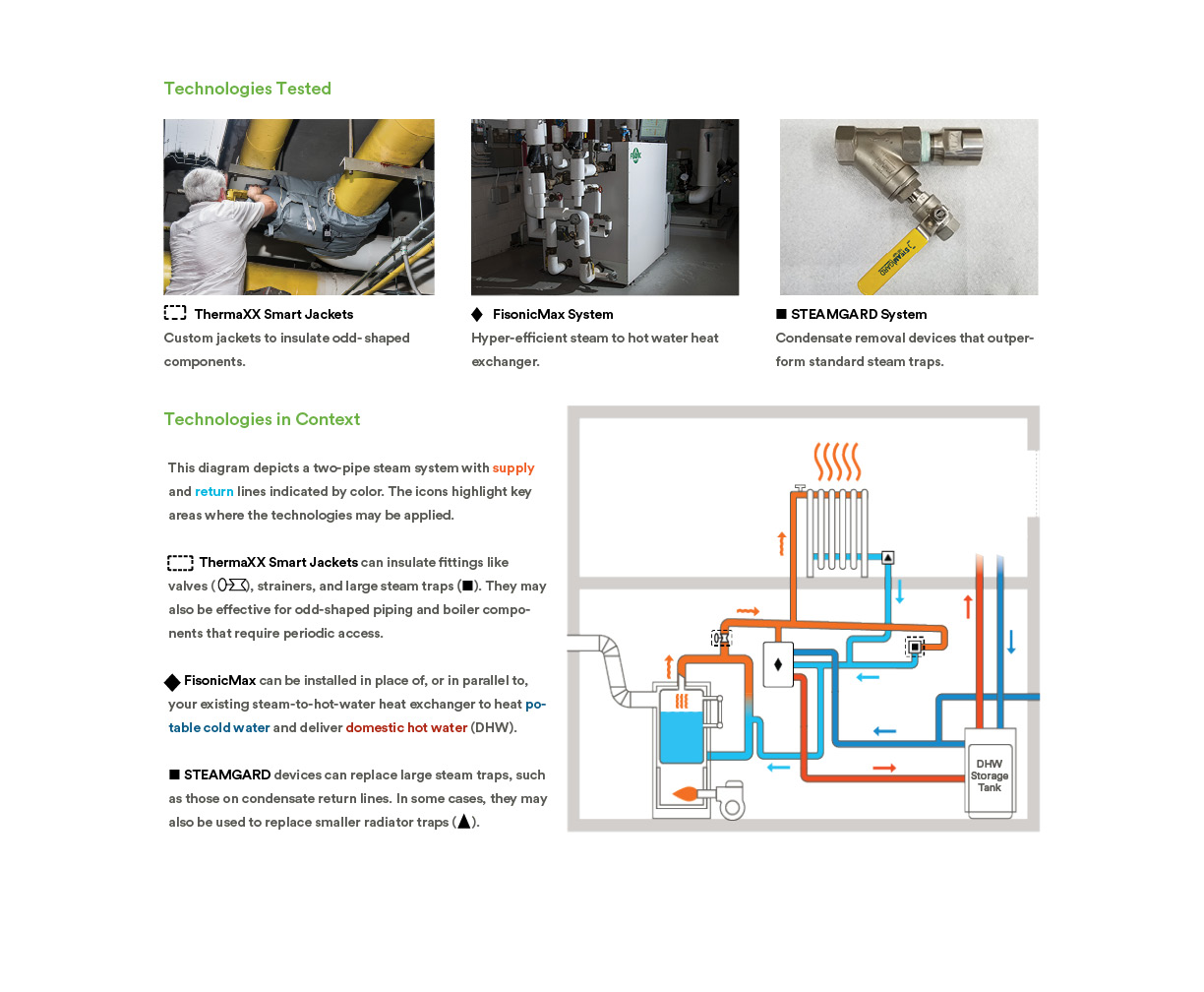

The following three steam system technologies were tested in City-owned buildings under the IDEA Program. DCAS DEM selected these technologies for their potential to resolve steam issues commonly encountered in NYC buildings, as well as their potential to be replicated and scaled across a wide variety of NYC building types.

Download the full case study to learn more about each technology and related demonstration project.

Facts about the building

(A) John Ericsson Middle School (MS126) & ThermaXX Smart Jackets

This NYC public school realized significant savings by installing custom insulation jackets for odd-shaped steam components. The installation also gave students an opportunity to learn about energy efficiency and innovative technology right in their school’s basement.

Fast Facts

- Demonstration Period: Nov. 2016- Jan. 2017

- Building Type: Public School

- Building Size: 160,800 gross sq. ft.

- Location: Greenpoint, Brooklyn

- Technology Installed: 29ThermaXX Smart Jackets

- Fuel Savings (natural gas): 8,675 therms/yr

- Emissions Reduction: 46 metric tons Co2e/yr

- Cost Savings: $8,068/yr

- Projected Payback: 3.1 years (with incentive)

- Incentive Provider: National Grid

(B): The NYC Public Health Lab & Hudson Fisonic

The NYC Public Health Lab installed Hudson Fisonic Corporation’s (HFC’s) high-efficiency, two-phase flow heat exchanger for domestic hot water service. The upgrade significantly reduced energy and water use without compromising performance.

Fast Facts

- Demonstration Period: Dec. 2016- Nov. 2017

- Building Type: Public Health Lab

- Building Size: 358,122 gross sq. ft.

- Location: Midtown Manhattan

- Technology Installed: FisonicMax Hot Water System

- Fuel Savings (District Steam) 21%/year

- Emissions Reduction: 12 metric tons CO2e/yr

- Quench Water Use Reduction: 100%

(C): The Metropolitan Pavilion & STEAMGARD

Replacing failed, conventional steam traps with STEAMGARD’s Condensate Removal Devices will reduce maintenance needs and energy use at this recreation center while keeping temperatures comfortable and consistent for staff and visitors.

Fast Facts

- Demonstration Period: Feb. 2017- Nov. 2018

- Building Type: Recreation Center & Indoor Pool

- Building Size: 18,200 sq. ft.

- Location: Williamsburg, Brooklyn

- Technology Installed: 58 STEAMGARD devices

- Est. Fuel Savings (natural gas): avg. 6,100 therms/yr

- Est. Emissions Reduction: 32 metric tons CO2e/yr

- Est. Cost Savings: avg. $6,400/yr

- Projected Payback: 2-3 years

Design Conditions

(A) MS 126 Challenge: Uninsulated Steam Fittings

For their 14-month IDEA demonstration project, MS 126 installed ThermaXX Smart Jackets for previously uninsulated steam system components. Smart Jackets are custom-fabricated, removable insulation covers designed for odd-shaped steam fittings. They feature wireless temperature sensors to record energy savings and provide additional monitoring and diagnostic services.MS 126 worked with ThermaXX engineers to conduct a heat loss survey, identify poorly insulated components, and estimate potential costs and savings.

Based on this analysis, the school installed 29 Smart Jackets, which yielded significant reductions in fuel use, emissions, and costs. The insulated jackets also kept ambient temperature in the school’s boiler room to a safe and comfortable 79 degrees, a welcome benefit for maintenance staff. Additionally, MS126 students toured the boiler room with DCAS staff to learn about the technology, energy use, and innovative sustainability solutions.

(B) NYC Public Health Lab Challenge: District Steam-to-Water Heat Exchangers

For the IDEA program, the NYC Department of Health and Mental Hygiene (DOHMH) Public Health Lab installed a FisonicMax Hot Water system. The Fisonic system is a hyper-efficient hot-water generating system that provides maximum heat transfer with precise control, thereby saving energy, reducing steam consumption, and eliminating the need for quench water.

For their IDEA demonstration, DOHMH installed the FisonicMax system and new condensate tank in their central heating plant. The compact system was installed in a control valve bypass arrangement, leaving the existing heat exchanger in place, which avoided system downtime and allowed comparative testing of the two systems. Ten months of comparative data showed that the FisonicMax system dramatically reduced steam trap losses, cut steam consumption for hot water, and entirely eliminated the use of quench water.

(C) Metropolitan Pavilion Challenge: Steam Traps

The Metropolitan Recreation Center, which features an indoor pool, fitness spaces, and classrooms, had long experienced issues related to steam trap failure, including non-existent heating in parts of the building. At the outset of the IDEA Program demonstration project, STEAMGARD engineers surveyed the recreation center’s steam system and identified problems and opportunities. Based on this analysis, engineers replaced 58 failed steam traps with STEAMGARD Condensate Removal Devices, which outperform conventional traps and can perform without degradation for up to 25 years. STEAMGARD engineers also completed needed repairs to damaged distribution piping.

The project resulted in immediate improvements with even heating restored across the entire recreation center. Staff and patrons also reported greater satisfaction with both ambient and pool temperatures.

Project Team

NYC Department of Citywide Administrative Services (DCAS), Division of Energy Management (DEM)

Building Energy Exchange (BE-Ex)

Conclusion

Additional Resources

Download the pdf below to learn more about each of the steam technologies and demonstration projects mentioned above. Visit DCAS Energy Management’s website to learn more about the IDEA program that made each of these demonstrations possible.

Begin with the Basics: Better Steam Heat

In addition to the innovative approaches described here, most steam-heated buildings will benefit from first completing the following tried-and-true scope of work:

- Boiler Clean & Tune + Burner Modulation – to improve boiler performance and efficiency.

- Master Venting – to help steam reach all radiators quickly and heat the building evenly.

- Multisensor Controls – to make the system responsive to changing heating needs.

- Thermostatic Radiator Valves & Orifice Plates –to deliver the right amount of heat to each space and provide occupants with more control over ambient temperature.

Read BE-Ex’s guide to Better Steam Heat to learn more about this scope of work and best practices for implementation.

This project was made possible with support from the NYC Department of Citywide Administrative Services